April - November 2017

Due to necessity (mainly cost of purchase and freight from overseas) I decided to scratch-build some Freight Wagons for my Bachmann 1:20.3 Consolidation to pull.

I started by scratch-building a number of chassis and bogies as a basis onto which I could then build on, the only things not scratch-built were the wheels and couplers.

All chassis were painted in Matt Black when their respective bodies were fitted.

Chassis

The chassis was made from;

- A piece of 3mm MDF 375mmx100mm

- Strips Miranti timber

- A piece of steel flat bar for added weight to some chassis that had light bodies

- Bamboo skewers for tension rods

|

| Underframe with tension rods (prior to bogie fitment) |

Bogies

The bogies were made from;

- PVC house molding for the bolster and axle boxes

- Styrene for the side frames, axle covers and coupler tongues

- Springs from washing pegs

|

| Side View |

|

| Top View |

|

| Springs |

|

| Painted and Installed |

Freight Wagons (Boxcars)

I built two (2) Freight Wagons (Boxcars) roughly following some plans for an outside frame boxcar as a guide for dimensions.

The plans came with a subscription to the old Garden Railways magazine

Body construction;

- The sides and ends are made from balsa wood that had strips of wood glued to them to give the impression of planks. These were then assembled into a rectangle and attached to the chassis, square pieces of timber were used to reinforce the corners and the bottom of the ends and sides where they attached to the chassis.

|

| End |

|

| Side View |

- The doors were made from craft (ice cream/paddle pop) sticks

- Small pieces of styrene were glued to simulate runners and a lock

|

| Door Detail |

- The roof was made from balsa wood sheet covered in lining fabric from a dressmaking shop.

Completed Wagon

Power Wagon

This wagon is a flat car onto which I built a steam driven generator plant.

Made from;

- The boiler from a Bachmann "Rogers" saddle tank locomotive,

- An old auto windscreen washer pump,

- A rotor from an electric motor

- A tape eject motor from a VCR

- and a small transformer from an old radio.

I used a standard chassis and covered the mdf with craft sticks to simulate planking. No weight was added as the cast metal pump is quite heavy.

Steam Motor

Generator and Transformer and Power Pole

Body construction;

- A standard chassis

- strips of wood for side planking

- strips of wood for stakes to hold the planking to make a gondola

Load Construction

- old plastic model cars and trucks found in a garage (car boot) sale to make a load of scrap bodies on the way to a wreckers for recycling

Completed Wagon

Tank Car

Body construction;

- A standard chassis

- One (1) piece of 100mm PVC pipe for the tank body

- Two (2) 100mm end caps

- Two (2) pieces of 90mm PVC pipe for inside the 100mm pipe to fit end caps

- Two (2) 32mm PVC end caps for the domes

- Two (2) Pieces of styrene for tank supports

- Two(2) pieces of styrene strip for tank banding

- Two (2) pieces of 90 degree styrene angle and flat strip for walkways with plastic flashing for checker plate detail

- Two (2) Plastic Washers and Two (2) Press Studs for dome openings operating wheels

- A piece of garden trellis for a ladder

|

| Tank Components |

|

| Dome Top and Walkway Detail |

Update;

December 2022 - January 2023

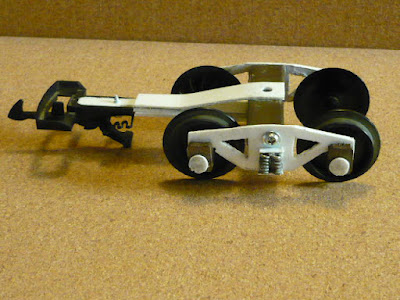

After buying a 3D Printer (Creality Ender3V2 with BLTouch fitted); I printed some bogies and knuckle couplers to replace the homemade bogies and the hook and loop couplers fitted to the wagons.

The files were downloaded from Yeggi

The new bogies are a lower profile and do reduce the rock that the wagons had a tendency to do.

Bogies

Link to Bogies file

Couplers

Link to Couplers files

Even though they are titled 1-32 they do not look out of place on the 1:20.3 wagons.

No comments:

Post a Comment